Advent of the MTP / MPO Connector

In today’s age of cloud computing and HD video streaming, the push for ever increasing bandwidth and ever decreasing footprint of communication equipment has been relentless. While fiber optic networks are inherently superior to copper in accommodating these requirements, they do pose specific challenges to the network infrastructure design and installation in particular.

A major challenge has been to effectively manage high-density fiber networks and facilitate a high volume of fiber connections between optical networking equipment and components within ever-tighter space constraints. For this purpose, the MPO connector format was developed and ultimately standardized by the International Electrotechnical Commission (IEC) in 1996. Compared to the single and dual fiber LC and SC connectors, the multi-fiber MPO (multi-fiber push-on) design significantly reduces the amount of time, effort and space required to deploy fiber network technologies.

While the MPO connector has been an integral part of data center implementations ever since, improvements to the original design resulted in the MTP (Multi-fiber Termination Push-on) connector. To ensure seamless and even faster deployments, the MTP connector was the first MPO connector to be factory-engineered to appropriate cable lengths. This meant less skill requirements for installation, better quality assurance and simplification of future additions or changes to the optical infrastructure. Ground-breaking at the time but the innovations introduced by the MTP connector eventually became industry standard. The MTP® connector is still evolving and the most technologically advanced multi-fiber connector on the market today, rivaling loss rates that single-fiber connectors saw merely a few years ago!

While MTP cable connectors and adapters provide significant enhancements over MPO, they are fully backward compatible with generic MPO Cable connectors and seamlessly integrate into existing MPO network designs.

MTP (High Performance MPO Connector) Components

At the heart of the MPO connector lies mechanical transfer (MT) ferrule technology, originally developed by NTT laboratories in the mid-1980s. This MT ferrule technology formed the basis of the MPO connector, introduced in the early 1990s. The primary function of a multi-fiber connector is to terminate a multi-fiber cable into an integrated connector. The connectors may be used to join different cables using adapters or to terminate links on cassettes in fiber patch panels. Please see the illustration below of the components of an MTP / MPO Connector.

Components of the Multi-Fiber Connector

Technical Improvements of MPO Connector Components

Due to drawbacks related to signal instability, insertion losses and accidental damage when joining connectors (also called mating), the original MPO connector design was revamped with enhancements in respect to its guide pins, spring and ferrule, resulting in significantly reduced signal loss and a more efficient, faster connection. This makes MTP an overall better option to terminate mult-fiber cables compared to the standard MPO connector.

Guide Pins:

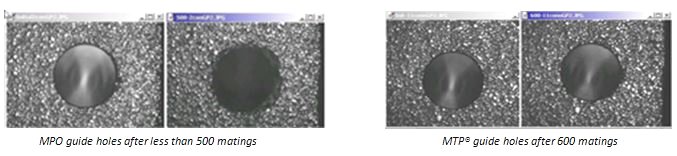

The function of the connector guide pins is to provide a controlled means of mating connectors in order to establish a secure and stable physical connection. The original MPO connector design uses an inferior plastic pin clamp which can lead to damaged pins when mating connectors multiple times. MTP connectors have guide pins attached to a recessed metal pin clamp, ensuring a strong clasp on the pins. This improved design minimizes the risk of accidental breaking when mating connectors. In addition to the improved clamp design, the MTP connector features an improved pin design. Whereas the pins on a standard MPO connector have sharp edges, the MTP fiber optic connector pins were redesigned with elliptical edges. This significantly reduced the wear and tear, damage and debris generation when mating the connector.

Spring:

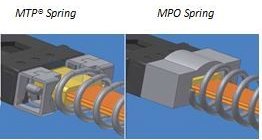

The spring of the connector provides the necessary force needed to establish and maintain constant physical connection during mating. The image on the left illustrates the difference between the springs used in the MTP and MPO connector. Because the MPO spring is unsecured, it can accidentally cause damage to the fiber ribbon. The MTP spring constrains the spring and its modified shape accommodates the full width of the fiber ribbon. This reduces the chance of internal damage when mating. For even more damage protection and to further shield your network, check out our line of Armored MTP Cables.

Ferrule:

The ferrule is the component which surrounds the fiber strands and maintains their position throughout the physical connection. A major improvement to the MPO connector was the introduction of the innovative floating ferrule design of the MTP connector. This allows all polished fiber tips in the ferrules to stay in contact while the connector housing rotates. This major step in the MTP connector’s evolution allowed multi-fiber connectors to provide an even more consistent and reliable performance. The floating ferrule feature was particularly important for applications in which the cable plugs directly into an active transceiver device and was an important reason MTP became the connector of choice for emerging optical transceiver applications.

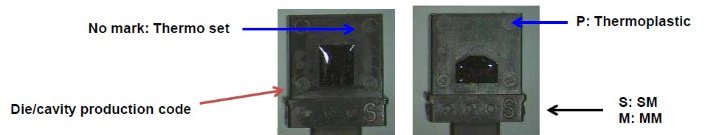

Another improvement of the MPO connector involved the original thermo-set compound design, which is more prone to moisture absorption and a main cause of performance degradation. Therefore US Conec migrated MTP’s original thermosetting ferrule technology to polyphenylene sulfide (PPS) thermoplastic injection molding. This thermoplastic material maintains a constant diameter for the guide holes, resulting in more reliable physical connection.

MTP / MPO Connector Summary

Major improvements to the original MPO connector design have led to the MTP and MTP Elite format that not only speed deployment of data center installations but also enhance performance and reliability. While the latest generation of MTP connectors is a big jump from the initial MT ferrule technology the improvements are still ongoing. MTP connectors deliver exceptional value for a vast range of network technologies and regardless of the technology you’re working with, MTP connectors should be part of your data center design.

Shop all MTP / MPO Connector Cables: MPO Connector Cables MTP Connector Cables MTP Elite Connector Cables

MTP®, MTP Elite® are registered trademarks of US Conec®