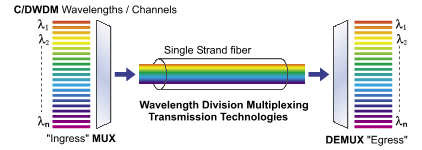

Fiber Optic cables come in many varieties and configurations and without going into too much technical detail, this guide provides a basic overview on commonly used terminology , typical configurations and best practice applications of Fiber Optic Cable Assemblies. A Fiber Optic Cable assembly consist of the fiber cable itself terminated with optical connectors on either end. An assembly terminated with merely a connector on one end is commonly referred to as a fiber optic pigtail. The increased popularity of fiber optics in general and optical fiber cables in particular, is driven by the ability to transport electro-magnetic (optical) signals over short and long distances more efficiently (at higher data rates combined with a lower loss rate, attenuation and a smaller footprint) than traditional copper (CAT5/6) cables.

Optical Fiber Cable History and Structure

As light doesn't travel around curves or corners, it is the principle of guiding light by refraction that makes modern Fiber Optic Communication and Cables possible. This “guiding of light” essentially involves confining the light signal to the optical core, which in the case of Single-Mode Fiber features a diameter smaller than a human hair! To prevent light escaping (leaking) from the optical core, a transparent cladding of lower refraction is applied around the glass (silica but sometimes plastic) fiber core so light Is reflected back into the core and leakage is kept to a minimum. The transition between the core and cladding can be sharp (step-index profile) or gradual (graded-index profile) and therefore have different dispersion characteristics and result in different effective propagation distances.

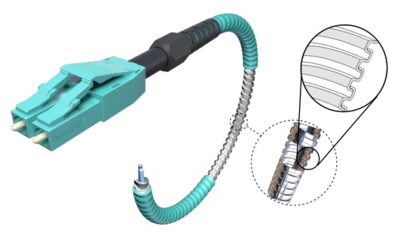

The cladding with a typical diameter of 125 micrometers (µm) is subsequently coated with a tough (modern cables feature a dual layer) resin, in order to protect the fragile core from physical damage due to micro - and macro bending, moisture and to minimize attenuation. To further safeguard the delicate fibers from unwanted damage, modern day optical cables come in a variety of sheathing, (armored) Jackets and insulation. These protective layers provide protection, strength and flexibility to the cable, yet do not compromise the optical wave guide properties.

Fiber Optic Cable Color and Mode

To browse our online catalog of Single- and Multimode fiber optic cable products:

Fiber Patch Cables

Specialty Fiber Cables

Armored Fiber Cables

Commercially available fiber cables, assemblies and patch cords can be ordered with jackets in any customized (shade of) color but standardized colors are used to identify the (generation of) Mode of the cable.