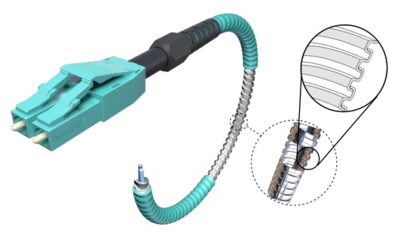

OptoSpan's SteelPatch and SteelFlex series of armored fiber optic cable assemblies provide a tactical solution to mission critical networks and next generation datacenters. The armored fiber cables feature military grade steel jacketing and allow for optical fiber installation in the most demanding and harsh environments.

Fiber Optic Technical Information & Documentation

- 14 MarRead more »

- 28 AprRead more »

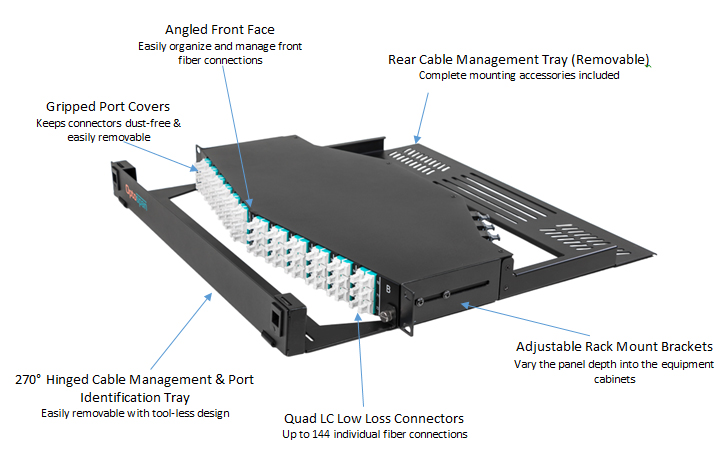

How to choose the appropriate Fiber Patch Panel?

Abstract:

The use of Fiber optic patch panels is widespread in today's network closets and data centers. However, because of the many options, configurations and embedded technologies, the decision of picking a suitable panel can be daunting. This article will provide the necessary information and selection criteria to make an informed decision on choosing the right one that will meet your organization's needs!

- 8 FebRead more »

WDM Multiplexers / Demultiplexers

Our article about Optical Multiplexing discussed the differences between popular WDM Technologies and the following article outlines the passive WDM multiplexers available with their respective specifications.

Introducing OptoSpan's line of passive optical BWDM, CWDM and DWDM multiplexer/demultiplexer modules that provide long haul optical communication featuring premium optical technology to expand and enhance fiber optic networks. These optical mux/demux modules provide low-cost bandwidth expansion and are easy to implement. Delivering low insertion loss, supporting protocols like ESCON, ATM, Fibre Channel, and Gigabit Ethernet over each port. Multiplexer Modules are available in 6 different modes including: * 4+2 Channel CWDM * 8+1 Channel CWDM * 8 Channel expansion CWDM * 8+1 Channel DWDM * 32 Channel DWDM * and 16+1 Channel DWDM*

Key Multiplexer Features:

- Bidirectional,

- 7 FebRead more »

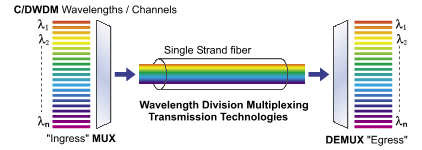

Optical Multiplexing Introduction

In recent years Fiber Optic communication technologies have evolved at a rapid pace in order to support our increasingly data driven society. Many of the advancements have been in the area of finding clever ways to increase the transmission capacity of the existing fiber network infrastructure. Since optical multiplexing is a useful technique to accomplish this, researchers have explored optimizing optical multiplexing in time (TDM), space (SMX) , polarization or phase (PDM) and wavelength (WDM).

WDM (Wavelength-Division Multiplexing)

While some of the aforementioned multiplexing techniques (in particular spatial Multiplexing) hold great promise for future applications, this article focuses primarily on Wavelength-Division Multiplexing (WDM) as it is the most widely used by SanSpot.com's applications, solutions and customers. In Essence WDM creates virtual fiber pathways over a single fiber strand by combining 2 or more wavelengths

- 11 JanRead more »

What is an MTP Fiber Connector?

MTP® is an acronym for Multi-fiber Termination Push-on and is the standardized terminating end of a multi-fiber cable that supports for all practical intents and purposes up to 24 fiber strands per connector. The MTP fiber connector is an improved, proprietary version of the standard MPO (Multi-Fiber Push-On) connector in respect to attenuation and reflection, yet uses the same form-factor and multiplex push-pul coupling type (SNAP). Developed by US Conec, the MTP connector increases overall performance by implementing structural improvements and higher quality materials.

The ferrule is same as MT (Mechanical Transfer) but is more easily reconnectable. Over time and under load, an MPO connector may show performance degradation and may compromise reliable transmission of high performance signals. Manufacturing improvements of its structural components have led to reduced insertion losses which will not change excessively under possible temperature fluctuations due to high amounts of traffic and a secure reliable connection can be maintained. The MTP optical connector is fully compliant with the MPO standard and therefore fully backwards compatible and capable of intermating with any MPO related equipment. For additional information, see the difference between MTP and MPO Connectors post.