How to choose the appropriate Fiber Patch Panel?

Abstract:

The use of Fiber optic patch panels is widespread in today's network closets and data centers. However, because of the many options, configurations and embedded technologies, the decision of picking a suitable panel can be daunting. This article will provide the necessary information and selection criteria to make an informed decision on choosing the right one that will meet your organization's needs!

Table of Contents

- What are Patch Panels?

- What is a Fiber Optic Patch Panel?

- Advantages of Fiber Patch Panels

- Selection Criteria for choosing the appropriate Fiber Patch Panel

- - Panel Location: Indoor / Outdoor, Rack or Wall Mount

- - Panel Capacity & Density: Loaded vs Modular/Unloaded, Number & Density of Ports, Footprint

- - Panel Compatibility & Performance: Performance, Polarity & Connector Type

- - Panel Design: Enclosed / Open, Angled vs Flat or Straight Design

What are Patch Panels?

Analog to a telephone switching board, patch panels are in essence centrally located appliances that provide interchangeable communication links to connected devices by means of patch cords and cables. In the case of wired networking, an intermediate patch panel provides structured cabling and fail-over capability avoiding the need of costly cable re-runs or unnecessary complex network configurations. Basically an array of communication ports of similar type, patch panels are typically used in the areas of computer networking and telecommunications.

In computer networking, patch panels provide link flexibility and portability of computer equipment like servers, workstations, switches etc., all the while keeping the network neat, organized and easy to manage. For example, physical and virtual moves of network devices and equipment (e.g due to user or device relocation) can be accomplished by a quick re-patching of patch cables on the patch panel.

Most wiring closets in buildings and Master Distribution Frames (MDF) in server rooms or Data Centers are designed based on this useful principle. With the exception of intelligent or smart patch panels, that require a power-supply and may have LED indicators for each port, a typical patch panel is passive and therefore does not provide conversion of signals and requires connected devices to have medium specific (e.g. HBA for Fiber Optic and NIC for Copper) interfaces. If not present, it will require active conversion devices like media converters, an optical transport network (OTN) switch or router in between to establish functional communication via the patch panel.

What is a Fiber Optic Patch Panel?

A Fiber optic patch panel, sometimes referred to as Fiber distribution panel is a dedicated patch panel for the termination of optical links and as such intended for use with optical patch cords and trunk cables only. This is an important distinction from copper-based patch panels that only provide connectivity to copper based Coaxial and (Unshielded) Twisted Pair (e.g. Category 5,6,7 and 8) cables and media. Copper based networks have been and still are popular as a so-called “last Mile” on premise cabling solution due to their relative cost effectiveness.

In the past and due to the fragile nature of fiber optic cables (bending, breaking, cleaning) fiber optic networks implied more complicated, difficult and expensive installations and confined the use of fiber optic patch panels to Data centers and single purpose (e.g. Storage Area) networks. With the arrival of more cost-effective optical switches, HBAs, improved performance and protection of the fragile glass fiber cables via armored jackets and bend-insensitive fiber, fiber to the desktop (FTTD) and fiber to the home (FTTH) has become a reality. Today more and more network closets are equipped with fiber patch panels and the use of fiber-optic patch panels is widespread…..Therefore a good understanding on how to select the appropriate panel or accessories is paramount for an efficient and effective optical network implementation.

A Typical Fiber Patch Panel

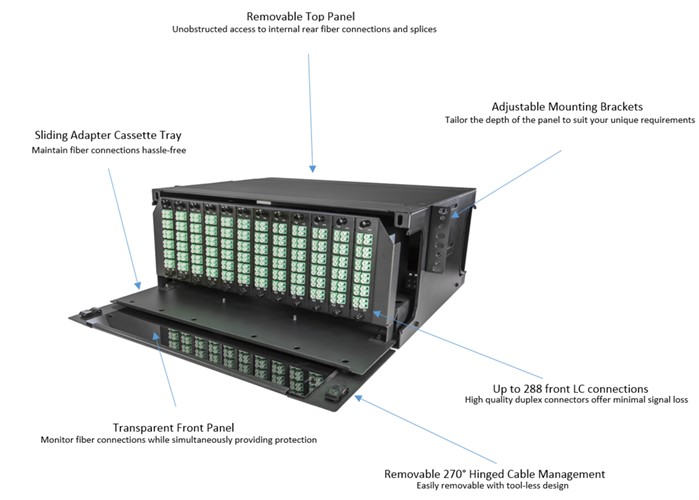

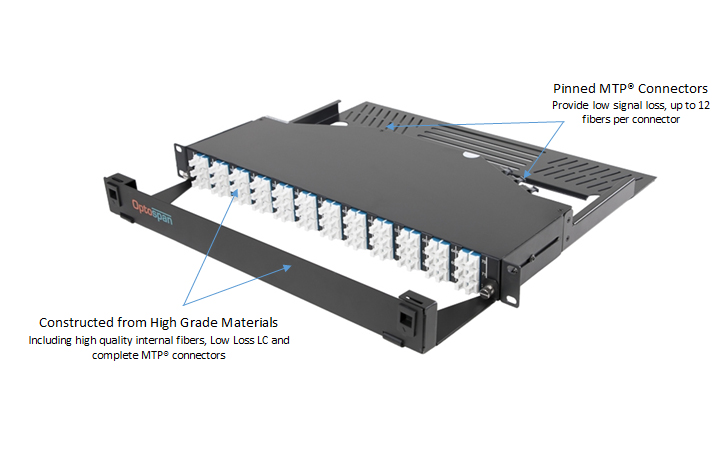

A basic fiber optic patch panel is essentially nothing more than a metal enclosure housing 1 or more fiber cassettes, fiber adapter plates or panels with an optional splicing kit and pigtails. A typical fiber patch panel is pictured below with the following features:

- Removable Top Panel

- Sliding adapter/cassette tray

- 288 Front LC ports

- Hinged cable management tray

- Transparent Front Panel

Selection Criteria for choosing a Fiber Patch Panel

As Fiber Optic Patch Panels come in many shapes, sizes and configurations they can be categorized according to the following selection criteria: Panel Location, Panel Design, Panel Capacity & Port Density, Panel Compatibility.

Panel Location

Panel Capacity & Density

- - Loaded vs Modular/Unloaded Panels:

Unloaded Panel

Unloaded Panel Fully Loaded Panel

Fully Loaded Panel - - Port Density & Rack space Footprint

Panel Compatibility & Performance:

Panel Design

- - Enclosed vs Open Patch Panels:

In order to provide protection from wear and tear, dust or dirt, many fiber panels are full depth and fully enclosed. This minimizes the risk of performance impairment or potential damage to the delicate fiber connections inside due to possible external factors like physical maintenance, servicing or implementation activity not necessarily related to the patch panel itself. Open panel design on the other hand makes use of fiber cassettes where the delicate fibers are pre-terminated and protected from potential damage inside the cassette. In this design the fiber patch panel itself is nothing more than a rack-mountable modular frame enclosure. Due to the lack of a protective enclosure the open panel design is not well suited for use with fiber adapter panels and splicing trays. The enclosed panels on the other hand can be configured with fiber adapter plates and optional splice trays. Please see the pictures below for regular enclosed full-depth and open design fiber optic patch panels:

Enclosed (with or without removable lid) patch panels are available in the High density and MPO series of fiber patch panels

- - Full depth vs shallow depth Panels:

Not only does every inch of rack space count In modern Data Center design but the effective management of airflow within a data center (rack) has become of equally importance. To mitigate obstruction of airflow and heat dissipation, shallow depth version patch panels have gained popularity in contemporary Data Center designs. Shallow depth panels are available in both open and enclosed design.

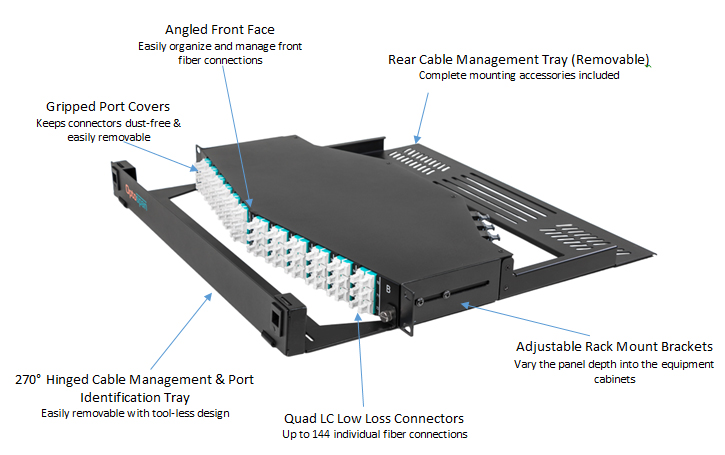

- - Angled vs Flat/Straight Design:

Angled fiber patch panels feature an angled front face and are designed with fiber cable management in mind. The angled front face facilitates easy management and guidance of the fiber optic cables to either the right or left side of the rack. This in contrary to the flat or straight face design of traditional fiber panels. Please see the pictures and videos below for examples of the different designs available in Optospan’s Ultra Density Patch Panels.

One of the first and easiest question to be answered is “What will be the panel's location?” as it will determine housing design, required protection and application. Will it be used indoor or outdoor, will it go inside a rack or mounted to a wall?

The second consideration is in respect to the fiber patch panel capacity and more specifically addresses the quantity, density and scalabilty of the amount of fiber ports / connections required.

As the name implies, loaded fiber patch panels come fully loaded/configured to the maximum allowed ports, cassettes or adapter panels a specific enclosure can handle, whereas the unloaded versions provide modular flexibility in expanding capacity, type or number of fiber ports.

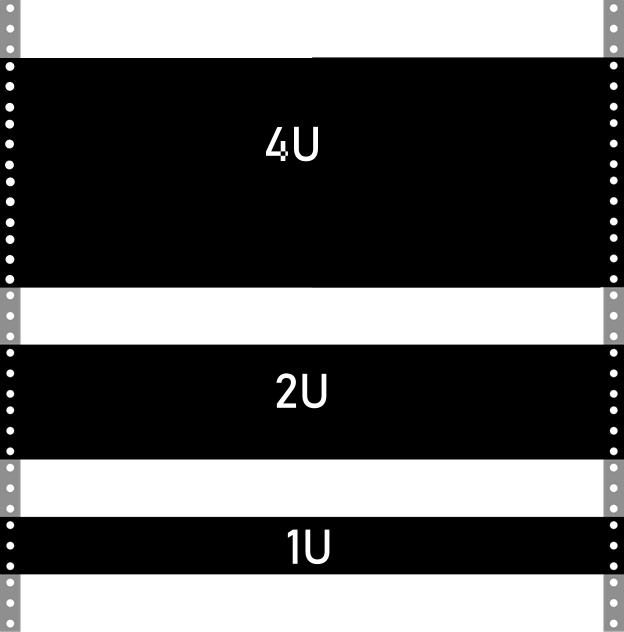

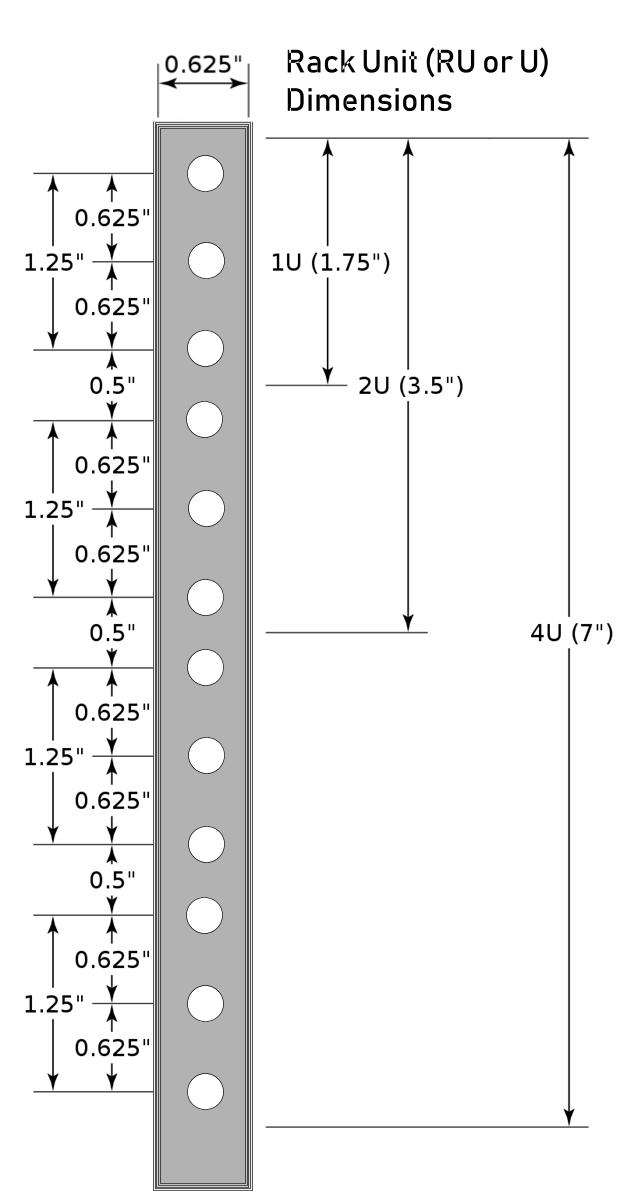

Most fiber optic patch panels are installed inside rack cabinets in server rooms, network closets or data centers. Rack space footprint in Data Centers comes at a premium making the density of number of fiber ports per rack-unit (RU) an important selection criteria. A rack unit (typically shortened to RU or U) is a unit of measure defined as 1 3⁄4 inches. Commonly used as a measurement of the overall height of standard (19 - or 23 inch) data center rackcabinets, or the height of equipment that mounts inside. The height of the frame or equipment is typically stated as multiples of rack units. E.g. a standard full-size rack cabinet is 42U high, while equipment is generally 1U, 2U, 3U, or 4U high.

Fiber patch panels typically come in either 1U, 2U or 4U heights. Above a picture of Rack Unit Cross section/Footprint. To the right and far right, actual dimensions and typical 1U, 2U and 4U Fiber Patch Panels respectively.

Fiber patch panels typically come in either 1U, 2U or 4U heights. Above a picture of Rack Unit Cross section/Footprint. To the right and far right, actual dimensions and typical 1U, 2U and 4U Fiber Patch Panels respectively.

1U Panel featuring 36 fiber ports

2U Panel featuring 144 fiber ports

2U Panel featuring 144 fiber ports 4U Panel featuring 288 fiber ports

4U Panel featuring 288 fiber ports

The third and possibly most important consideration in picking a patch panel revolves around the performance, polarity & connector type of front and rear connectors. Panel compatibility is essentially dictated by the fiber optic equipment and components requiring optical connectivity via the patch panel. Typical duplex Single - or Multimode optical links require LC or SC connectors of either the UPC or APC variety. However, due to next generation 40G and 100G networking and the use of more advanced multi-fiber connectors and pluggables (e.g. QSFP+), design and layout of a fiber patch panel may call for specific polarity requirements. Multi-fiber Polarity types or methods that can be distinguished are methods A, B, C or Z. Performance is directly related to the embedded technology for aggregation of rear end connectors that come in either MPO, MTP and MTP Elite variety. Said considerations are reflected in OptoSpan's series of patch panels: Ultra Elite, Ultra & High Density and the MPO series of fiber patch panels:

. Open Panel featuring Fiber cassettes

Open Panel featuring Fiber cassettes Fully enclosed full depth Panel

Fully enclosed full depth Panel Shallow depth Enclosed Panel

Shallow depth Enclosed Panel Shallow depth Open Panel

Shallow depth Open Panel

Angled Front Face Panel

Angled Front Face Panel Angled Panel Design

Flat Front Face Panel

Flat Front Face Panel

Flat Front Panel Design

Flat Front patch panels feature a straight front face and is standard on most fiber patch panels.

Summary:

Selecting a fiber patch panel can be daunting and at certain times confusing. This article explores most common considerations, selection criteria and options available for picking the appropriate patch panel for most IT infrastructure environments. While trying to be complete, there may still be some unanswered questions and specific situations that warrant additional information. Don't hesitate to contact us for a obligation free consultation to assess your specific situation and what fiber patch panel will meet your requirements and expectations.

Ultra Elite Series

Ultra Elite Series Ultra Density Series

Ultra Density Series High Density Series

High Density Series MPO Series

MPO Series